Research Article | DOI: https://doi.org/10.58489/2836-2187/017

Examining the Ability of Caulobacter crescentus and Sphingomonas sp. to Degrade Plastics

- Suneetha T B*, 1

- Aayush Prasad Joshi 1

- Ashwini K. M 1

- Sangeetha S 1

- Suraj G 1

- Nikhilesh Janak Katira 1

1Department of Biotechnology, Acharya Institute of Technology, Soladevanahalli, Hesaraghatta Road, Bangalore- 560107

*Corresponding Author: Suneetha T B*,

Citation: Suneetha T B, Aayush Prasad Joshi, Ashwini K. M., Sangeetha S., Suraj G., Nikhilesh Janak Katira (2023). Examining the Ability of Caulobacter crescentus and Sphingomonas sp. to Degrade Plastics. Journal of Microbes and Research. 2(2); DOI: 10.58489/2836-2187/017

Copyright: © 2023 Suneetha T B, this is an open-access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received: 11 March 2023 | Accepted: 12 September 2023 | Published: 19 September 2023

Keywords: Plastic degradation, biodegradation, Caulobacter crescentus, Sphingomonas sp.

Abstract

Plastic pollution is one of the major problems faced all over the world. All living beings are severely affected by the accumulation of plastics in their habitats over the years. Natural decomposition of plastic takes a very long time to occur. Microbial biotechnology has the potential to deal with the plastic wastes in a sustainable manner. As a result, various types of bacteria have been identified from soil and other sources that are capable of decomposing plastic more quickly. Here, we considered the bacterial species Caulobacter crescentus and Sphingomonas sp. whose families are reported to be associated with plastic-degrading microbial environment in the studied research papers. These bacteria were inoculated in plastic-containing medium to examine their polymer breakdown properties.

Introduction

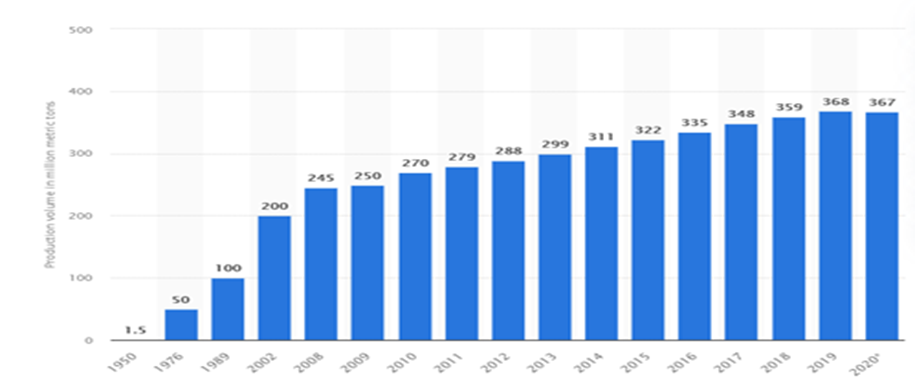

Plastics are man-made long chain polymeric units. Plastics have become an indispensable part of our life. A key breakthrough came in 1907, when Belgian-American chemist Leo Baekeland created Bakelite, the first real synthetic, mass-produced plastic [2]. In a wide range of items, plastics are utilised and other formerly used materials for applications dominated by plastic, such as wood, metals and glass have been removed. In 2019, the global production of plastics reached 368 million metric tons [3]. Europe was responsible for production of 57.9 million tons of plastic in 2019. China is one of the world's major plastics manufacturers, with more than a quarter of worldwide output [3]. Plastic imports are continuously growing in the United States and China is the leading provider. In the previous ten years, Chinese plastic exports have expanded significantly; in 2009, the value of exports came to USD 14.4 billion, and increased by 2019 to USD 48.3 billion [3]. Since the early 1950s, researchers estimate that over 8.3 billion tons of plastic have been manufactured [1]. About 60% of this plastic ended up at a deposit or in the natural environment [1]. Fig.1 displays the annual plastic output between 1950–2020 [1]. Production is expected to decline by around 0.3 percent in 2020 owing to the impact of COVID-19 on the sector [3].

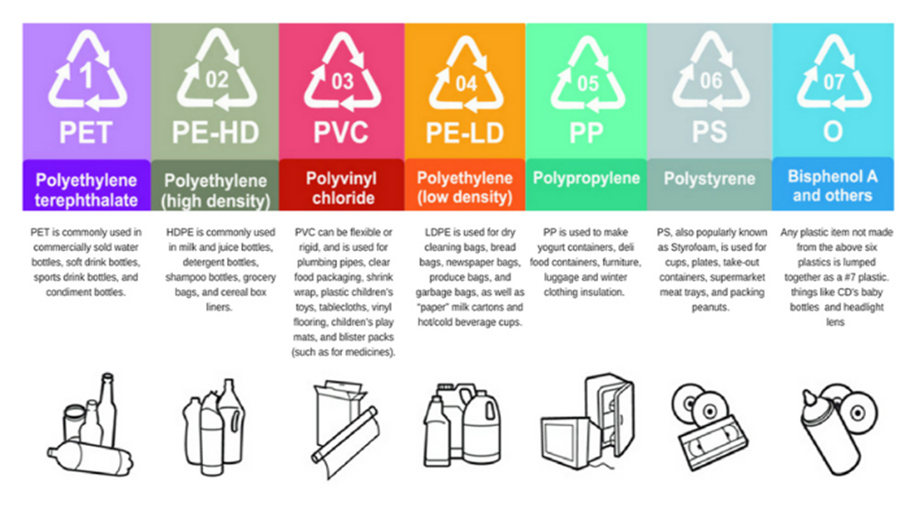

Table 1 shows the most popular types of plastics such as PET, LDPE, HDPE, PP, PVC, PS and others. These seven are plastics that cannot be degraded naturally. Fig.2 shows the products of these seven plastics and their identification. Excluding these, the most popular biodegradable plastics are PLA, PVA, PBS and others.

Plastic degradation: Any modification of the polymer or chemistry owing to a variety of environmental factors, including light, temperature, humidity, chemical conditions or organic activity [10] is referred as plastic degradation. Those processes that alter the polymer properties due to physical, chemical or biological interactions are known as polymer breakdowns.

Plastic degradation by micro-organisms: The micro-organisms on the plastic surface produce enzyme in microbial degradation that may break bonds between carbon polymers and utilize it as a source of carbon [8] [12][13]. These enzymes breakdown plastic, or return the polymers to their monomer state before they are produced [4][6][10].

In the year 2013, the term “plastisphere” was coined, to refer the life around the plastic wastes dumped in the environment [14]. The taxa of micro-organisms in the plastisphere differs based on the habitat (land, marine, freshwater, etc.). There are numerous researches carried out to uncover the strains of the microbial communities on the plastic debris. Grazia et.al.[7] and Joel Ruthi et.al.[9] mention Caulobacterales and other Proteobacteria in the marine ecosystem forming the plastisphere. Sphingomonas genus is noted for their abilities to degrade polyvinyl alcohol (PVA) [5] and polycyclic aromatic hydrocarbons (PAHs) [15].

Factors affecting plastic degradation by micro-organisms [4][10]: There are several various factors that affects the plastic degradation rate. aa

A. Moisture content: Water is very crucial for existence of micro-organisms. The microbial activity is said to be increased when there is a proper amount of water content is present.

B. pH: The variation of pH level effects the growth of micro-organism and thereby hinders the rate of plastic degradation also.

C. Temperature: Whenever there is an increase in temperature, this leads to destruction of micro-organisms. There-fore the rate of plastic degradation gets affected.

D. Molecular weight: As the weight of plastic sample increases, it also takes more time for the micro-organisms to degrade the plastics. We can say that molecular weight is inversely proportional to the rate of plastic degradation.

E. Surface area: As the surface area is increased, this facilitates the micro-organisms to degrade plastic easily and smoothly.

Fig 1: Graphical representation of annual plastic production 1950-2020

Fig 2: Type and identification of non-biodegradable plastic

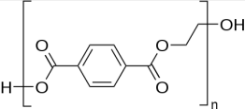

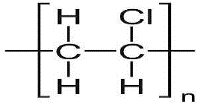

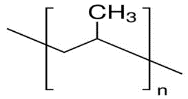

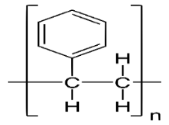

Table 1: Non-biodegradable plastics and their structures

| Name | Description | Structural Formula |

PET (Polyethylene Terephthalate) | This is one of the plastics used most frequently. It is light, durable, often transparent and commonly used in food packaging and manufacturing (polyester). |

|

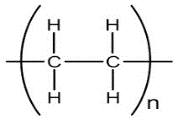

HDPE (High-Density Polyethylene) | High-density petroleum-based polyethylene is humidity and chemical resistant, which makes it excellent for cartridges, containers, tube and other construction components. |

|

LDPE (Low-Density Polyethylene) | Polyethylene with lower petroleum density is a version of HDPEs which is more soft, clearer and more flexible. It is generally utilized as a liner in cards and in corrosion-resistant surfaces and other items. |

|

PVC (Polyvinyl Chloride) | PVC is strong, stiff and chemicals-resistant and weathering resistance, making it desirable for construction and building applications. |

|

| PP (Polypropylene) | PP is heat-resistant to other types, so that it is suitable for food and food storage products that are intended to store hot product or heat themselves. |

|

| PS (Polystyrene) | PS is cheap and is extremely effectively isolated, making it an essential element in the food, packaging and construction sectors. |

|

| Others | This category is a comprises of additional plastic kinds, which do not fall into any of the other six classes or are numerous type combinations. For this plastic kind, the code for recycling is 7.

|

|

Materials And Methods

Plastic Sample Collection: Three daily using plastic products of types HDPE, LDPE and PVC were identified based on recycling symbols labelled on them.

Bacterial Specimen Collection: The bacterial strains of Caulobacter crescentus and Sphingomonas sp. were obtained from Microbial Type Culture Collection and Gene Bank (MTCC), Chandigarh, India.

Pure Culture Preparation: Nutrient broth was used to create a pure culture of Sphingomonas sp. and Caulobacter crecentus. In a 500ml conical flask, 3.25 gram of Nutrient broth was mixed with 250ml of distilled water. The solution was sterilized in an autoclave for 15 minutes at 15 pounds of pressure and 121 degrees Celsius.

Pre-treatment of the Plastic samples:

The plastics were cut into small strips of varying dimensions as shown in Fig.3, initially weighed and transferred to beaker containing 18ml Tween, 10 ml disinfectant (5g NaCl, 5g NaOH and 10ml glacial acetic acid) and 225ml of distilled water and stirred for 45-60 minutes. Then the traces of the solution in the strips were removed by subjecting to stirring with distilled water. Then they were alternatively kept in hot-air oven at 60℃ for 1-2 hours and in acetone solution for 30 minutes. This cycle was repeatedly done around 10 times and later the strips were exposed to UV light for sterilization.

Incubation of plastic samples in culture media:

The culture media was prepared by adding 30g Tryptic Soya Broth in 1 litre of distilled water and was divided into nine conical flasks. The inoculum of Caulobacter crescentus, Sphingomonas sp. and both strains were added into three sets of conical flasks as shown in Fig.4, each set containing different plastic samples under aseptic conditions. These flasks were incubated in incubator shaker at 36° C for 30 days.

% Weight loss = (Initial weight – Final Weight) *100

Initial Weight

Assessment of plastic degradation:

The plastics were removed from the conical flasks, washed and dried thoroughly. They were weighed using an electronic balance to get final weight. The degradation is determined by the percentage loss of weight given in the equation below:

Fig 3: Top-to-bottom: First row- PVC plastic strips; Second row (Left-to-right)- LDPE plastic strips, HDPE plastic strips

Fig 4:Plastic samples incubated in conical flasks

Result

Contrary with the initial literature review the bacteria was able to digest biodegradable however it was not able to show similar characteristics for non-biodegradable plastic or petroleum-based plastic. Various sort of per-treatmen was done to the plastic sample which help in relaxing the affinity of carbon carbon bond. The starting and end weights of the plastic strips are contrasted in Table 2. The greatest weight loss for Caulobacter crescentus cultured with LDPE was 3.1250%. The values do not guarantee that bacteria will cause deterioration. The results of this experiment demonstrate that Caulobacter crescentus and Spinghomonas sp. bacteria were unable to break down the non-biodegradable plastic. They are ineffective even in the situation where both microorganisms were operating on the plastic. Although we have seen LDPE plastic degrade in all three circumstances, the evidence is not strong enough to conclusively demonstrate that these bacteria can degrease LDPE plastic. As the edged radiation for HDPE and PVC is less than 1%, there has been no bacterial impact on those plastics.

Table 2: Assessment of plastic degradation by measuring their initial and final weights

Plastic type | Bacterial strains used | Initial weight (In grams) | Final weight (In grams) | %Weight loss |

| HDPE | Caulobacter crescentus | 0.2937 | 0.2919 | 0.6128 |

| Sphingomonas sp. | 0.3195 | 0.3176 | 0.5946 | |

| Both | 0.2724 | 0.2710 | 0.5139 | |

| LDPE | Caulobacter crescentus | 0.0736 | 0.0713 | 3.1250 |

| Sphingomonas sp. | 0.0907 | 0.0882 | 2.7563 | |

| Both | 0.0672 | 0.0652 | 2.9762 | |

| PVC | Caulobacter crescentus | 0.6917 | 0.6909 | 0.1157 |

| Sphingomonas sp. | 0.9227 | 0.9220 | 0.0759 | |

| Both | 0.6966 | 0.6964 | 0.0287 |

Discussion

As the result table shows no major difference in the weight of plastic samples before and after incubation i.e. the % weight loss was lesser than 5% in all conditions, hence there was no significant plastic degradation observed by the bacteria Caulobacter crescentus and Sphingomonas sp. Even with pretreatment of plastics mechanically, with heat and UV light, to assist the degradation process, positive result was not obtained.

Conclusion

The best future solution to the plastic problem is the discovery and usage of micro-organisms capable of plastic breakdown. However, in this experiment, the species of Caulobacter crescentus, Sphingomonas sp. given the required conditions showed no degradation of the plastic types HDPE, LDPE and PVC. Also there exists advance technologies to determine plastic degradation that needs to be adapted during the experiment [11] but we failed to do so as the basic weight analysis of the plastics gave negative results.

Acknowledgement

This study was carried out in Acharya Institute of Technology, Karnataka, amidst COVID-19 pandemic lockdown rules and regulations. We thank our former lab instructor Mrs. Sake Swetha for the help during the course of experiment.

References

- Our planet is drowning in plastic pollution—it's time for change”. UNEP, https://www.unep.org/interactive/beat-plastic-pollution/. Accessed 13/06/2022

View at Publisher | View at Google Scholar - “Plastics: a story of more than 100 years of innovation”. Plastics Europe, https://www.plasticseurope.org/en/about-plastics/what-are-plastics/history.Accessed 12/06/2021

View at Publisher | View at Google Scholar - Ian Tiseo, “Annual production of plastics worldwide from 1950 to 2020”. Statista, https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/. Accessed 12/06/2021.

View at Publisher | View at Google Scholar - Iram, D., Riaz, R., & Iqbal, R. K. (2019). Usage of potential micro-organisms for degradation of plastics. Open J. Environ. Biol, 4(1), 7-15.

View at Publisher | View at Google Scholar - Kim, B. C., Sohn, C. K., Lim, S. K., Lee, J. W., & Park, W. (2003). Degradation of polyvinyl alcohol by Sphingomonas sp. SA3 and its symbiote. Journal of Industrial Microbiology and Biotechnology, 30(1), 70-74.

View at Publisher | View at Google Scholar - Mahdiyah D., Elpawati, Bayu H. M.., (2013). Isolation of polyethylene plastic degrading-bacteria, Biosciences International, 2(3), 29-32

View at Publisher | View at Google Scholar - Quero, G. M., & Luna, G. M. (2017). Surfing and dining on the “plastisphere”: Microbial life on plastic marine debris. Advances in Oceanography and Limnology, 8(2).

View at Publisher | View at Google Scholar - Rose, R. S., Richardson, K. H., Latvanen, E. J., Hanson, C. A., Resmini, M., & Sanders, I. A. (2020). Microbial degradation of plastic in aqueous solutions demonstrated by CO2 evolution and quantification. International journal of molecular sciences, 21(4), 1176.

View at Publisher | View at Google Scholar - Rüthi, J., Bölsterli, D., Pardi-Comensoli, L., Brunner, I., & Frey, B. (2020). The “plastisphere” of biodegradable plastics is characterized by specific microbial taxa of alpine and arctic soils. Frontiers in Environmental Science, 8, 562263.

View at Publisher | View at Google Scholar - Tokiwa, Y., Calabia, B. P., Ugwu, C. U., & Aiba, S. (2009). Biodegradability of plastics. International journal of molecular sciences, 10(9), 3722-3742.

View at Publisher | View at Google Scholar - Tosin, M., Weber, M., Siotto, M., Lott, C., & Degli Innocenti, F. (2012). Laboratory test methods to determine the degradation of plastics in marine environmental conditions. Frontiers in microbiology, 3, 225.

View at Publisher | View at Google Scholar - Vaksmaa, A., Knittel, K., Abdala Asbun, A., Goudriaan, M., Ellrott, A., Witte, H. J., ... & Niemann, H. (2021). Microbial communities on plastic polymers in the Mediterranean Sea. Frontiers in microbiology, 12, 673553.

View at Publisher | View at Google Scholar - Venkatesh, S., Mahboob, S., Govindarajan, M., Al-Ghanim, K. A., Ahmed, Z., Al-Mulhm, N., ... & Vijayalakshmi, S. (2021). Microbial degradation of plastics: Sustainable approach to tackling environmental threats facing big cities of the future. Journal of King Saud University-Science, 33(3), 101362.

View at Publisher | View at Google Scholar - Zettler, E. R., Mincer, T. J., & Amaral-Zettler, L. A. (2013). Life in the “plastisphere”: microbial communities on plastic marine debris. Environmental science & technology, 47(13), 7137-7146.

View at Publisher | View at Google Scholar - Zhou, L., Li, H., Zhang, Y., Han, S., & Xu, H. (2016). Sphingomonas from petroleum-contaminated soils in Shenfu, China and their PAHs degradation abilities. brazilian journal of microbiology, 47, 271-278.

View at Publisher | View at Google Scholar